Offering a full range of artificial lift solutions, we are equipped to help operating companies optimize their artificial lift operations, whether ESP, Rod Lift, Gas Lift, Plunger Lift, or Capillary Services. We bring together breakthrough solutions, such as our BLAZE® surface treatment, with a commitment to working closely with our customers to optimize the reliability, efficiency, and productivity of their artificial lift operations.

Proven Lift Technology

An important element in our commitment to our customers is our development and application of technology that can contribute to the success of artificial lift operations. One technological breakthrough that has impacted all lift processes is our BLAZE surface treatment. BLAZE is proven to increase the run life of couplings, rod guides, gas lift mandrels, plungers, trim kits, ESP stages, and more by up to 5x.

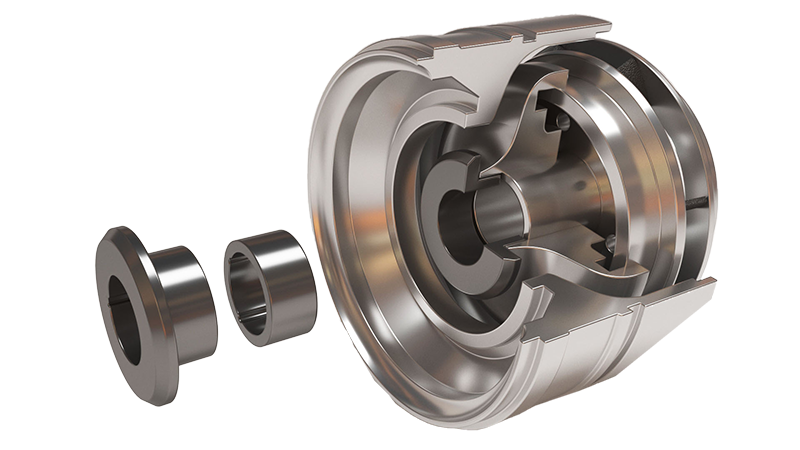

ESP

Endurance Lift provides comprehensive ESP systems, including pumps, all sensors, intake and gas handling equipment, VSDs, conventional motors and PMMs, and power control systems. For ESP operations, BLAZE surface treatment has been demonstrated to increase the life of both AR bearings and stages.

Gas Lift

Supporting gas lift operations are Endurance Lift valves, mandrels, packers, on/off tools and stingers, profile and seating nipples, and various tubing accessories. In gas lift applications, BLAZE-treated mandrels have been demonstrated to better withstand a wide range of downhole conditions and provide significantly longer life than conventional mandrels.

Rod Lift

Our advanced FSR (Fiberglass Sucker Rods) allow customers to increase production without having to up-size beam unit equipment. We also supply API standard and specialty rod pumps, proven to provide a combination of high performance and long life. Covering all of your rod lift equipment requirements, we offer a comprehensive selection of TAC products and components, as well as BHAs and wellhead equipment We further support this market with rod inspection services that help customers attain maximum life for sucker rods.

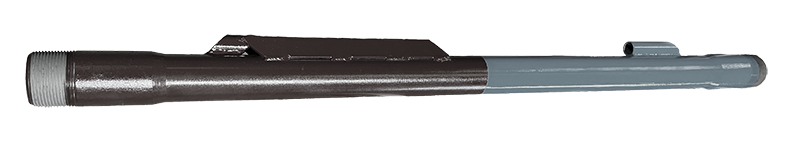

Plunger Lift

Endurance Lift offers a broad selection of plunger types to help operators match plungers to the demands of the production decline curve. In addition, we manufacture key supporting components such as motor valves, wellhead lubricators, and chokes. BLAZE-treated plungers have been demonstrated to increase plunger run life by more than 3X, adding to the value that Endurance Lift brings plunger lift.

Capillary Services

Endurance Lift’s Capillary Services are designed to improve well productivity and the run life of downhole artificial lift equipment. In addition to Capillary Services, Endurance also provides related equipment, including downhole injection valves, injection manifolds, chemical injection mandrels, TACs, various metallurgies for specific capillary applications, and banding material and cannon clamps.

Working in Partnership

We appreciate the importance of the word “service” in our designation as an “oilfield service company,” and our commitment to our customers is a core value that guides our actions every day. We are driven to be an artificial lift services company on which customers can rely, day in & day out. We bring together breakthrough technologies that span the production curve with a level of service that creates lasting partnerships with our customers – from initial field analysis to implementation and training.

An important element of our service offering is our WellIntel™ program, a robust equipment monitoring platform. WellIntel enables customers to audit our equipment’s performance by well, lease, field, asset, or basin, providing a digital healthcare record for your well’s equipment.

For more information on Endurance Lift’s Life of the Well services, please visit our contact page or email us at [email protected].