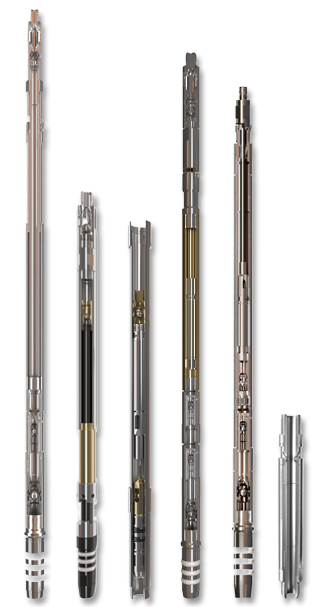

A recent survey of production personnel indicated that rod pumps were seen as the second most failure-prone component in a rod lift system. There are many causes of rod pump failure, but a significant factor can be employing a pump whose design and characteristics are not in line with the demands of the pumping application. That is why we offer a broad range of API-Modified Rod Pumps, which are supported by our experienced industry experts. Included in our API-Modified Rod Pump line are the following types:

Endurance Mercury Rod Pumps – three versions, offered in a wide range of metallurgy, all designed to handle various solids and prevent stuck rod pumps

- Mercury Stationary Barrel Pump – designed for heavy sand applications with lower gas volumes. To alleviate the potential of build-up around the barrel, this pump can be outfitted with high-flow bottom discharge valve(s)

- Mercury Traveling Barrel Pump – designed for lower volume, shallow wells, where solids settle around the seating nipple. This pump keeps these solids in suspension with each stroke

- Mercury Tubing Barrel Pump – designed for applications where higher fluid volumes and solids are encountered.

See how Endurance Mercury Pumps achieved 11X and 8X run life improvements.

Endurance Sand Pusher Pump – designed to effectively move foreign material out on the down stroke – frac sand, formation sand, iron sulfide, etc. – that would otherwise disable conventional insert pumps.

Endurance Optimizer Rod Pumps – available in any API insert pump size, are designed for applications where moderate levels of sand and gas are present. Optimizer Rod Pumps can be used in both vertical and horizontal applications.

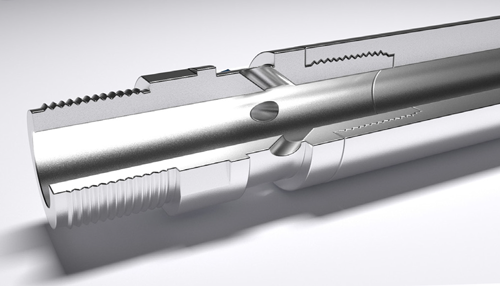

Stationary Barrel Pump with Game Changer® Vented Pin Plunger and Bottom Discharge Valve(s) – engineered for long life in demanding wells where high levels of corrosion and sand concentrations are found. Can be Tungsten spraymetal- or BLAZE®-treated surface, providing unmatched protection from the effects of corrosion and abrasive sand. In addition, the Game Changer is also able to clear solids away from the leading edge of its spray by introducing fluids just above the upper end of the spray. Based on Game Changer’s unique design, it has been proven to effectively handle high concentrations of both sand and iron sulfide.

See how the Game Changer achieved 2.5x improved run life in demanding well conditions.