Note: This is the second of two blogs detailing Endurance Lift’s innovative approach to ESP. This blog will focus on BLAZE® surface treatment technology and how it improves the run-life performance of ESP equipment. The first part can be found here.

Technology is the key driver for higher oil production, operating efficiency, and reliability. This is particularly true in ESP operations, where high temperature, corrosive conditions, gas, sand, and paraffin represent an ongoing challenge to equipment life and reliable operations.

Endurance Lift continues to emphasize innovative thinking and advanced technology to meet the challenge of providing ESPs that deliver longer life and more reliable operation, even in the harshest downhole environments.

BLAZE® AR Bearings Extend Run Life by 5X

A large operator in the Powder River Basin was dealing with significant gas-slugging conditions, leading to low- or no-flow fluid rates and ESP run times of approximately 35 days. These fluid rates contributed to extreme downhole heat and thermal shocking of Tungsten Carbide (TC) bearings. The overall result was fracture failures and catastrophic damage to surrounding downhole components.

To solve this problem, the conventional TC bearings were replaced with BLAZE®-treated bearings. With no other changes, the new ESP system, featuring BLAZE® AR bearings, surpassed the performance of conventional installations by more than 5X.

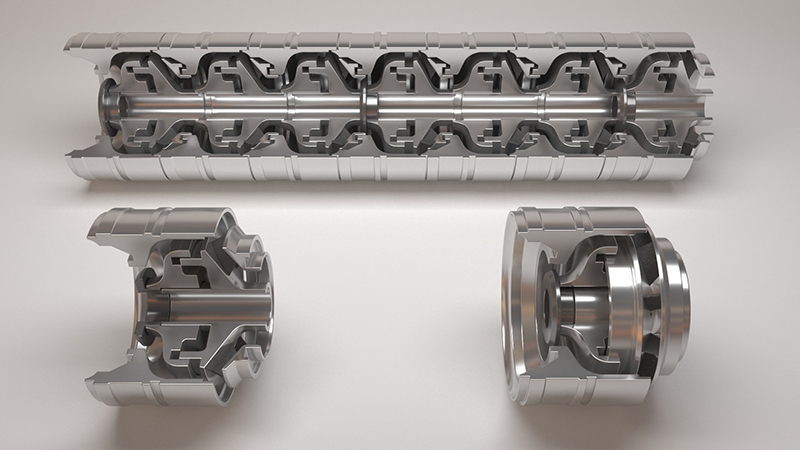

BLAZE®-Treated Stages Surpass Historical Run Life Average By 2X

A large operator in the Bakken was dealing with below-average run times for ESP systems due to the wells’ high solids levels. The run times for initial ESP installations in this field averaged just 155 days before abrasion from solids would erode pump components, leading to catastrophic failure of the ESP. The operator agreed to test Endurance Lift’s ESP with BLAZE®-treated stages on two wells, as a possible answer to the problem of short run times.

Endurance Lift deployed two ESP systems utilizing BLAZE® stages, each including BLAZE®-treated impeller and diffuser components. Both systems surpassed the operator’s historical ESP system run life by more than 2X, one achieving a run life of 315 days and the other still running after more than a year.

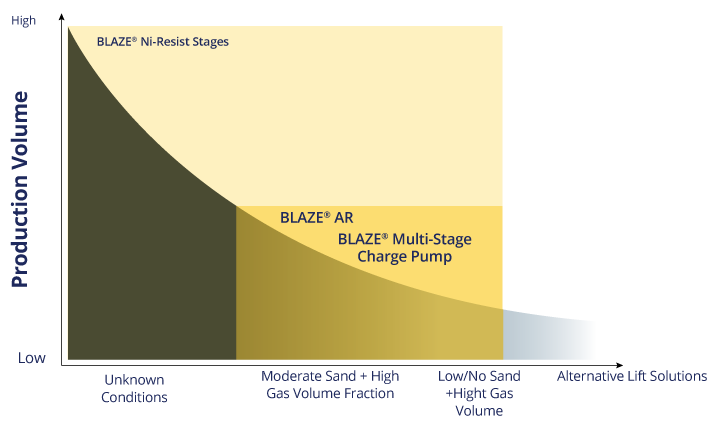

BLAZE®-Treated ESP Components – Designed to Increase Run Times for the Life of the Well

As established above, our ESP components with BLAZE® technology have been proven to deliver superior performance in harsh wellbore conditions and extend run life in a manner that reduces field maintenance requirements. The chart below further details where BLAZE® components are most applicable in various ESP application conditions.

How Our Advanced Technology Can Help Your ESP Operation

Endurance Lift Solutions offers a full suite of advanced application-specific equipment to meet your ESP needs.

Our Genesis™ Advanced Gas Handling System is proven to solve the problems associated with gas interference and high motor temperatures. This proven system has also provided an effective solution to wells experiencing low intake pressures and increasing gas volumes, resulting in severe gas interference, short runs, and production losses. In another problematic application – a well experiencing a high gas-to-fluids ratio – the Genesis™ system provided for a smooth drawdown with no gas-related downtime.

(More detailed information on the Genesis™ Advanced Gas Handling System can be found in the blog, Innovative ESP Technology For The Life of the Well – Part 1.)

At Endurance Lift, we welcome the opportunity to collaborate with you to create innovative solutions to your EPS challenges. For more information, please contact us at [email protected] or contact Garrett Burbank at 307-250-5870.