Optimizing the Run Life of Artificial Lift Systems

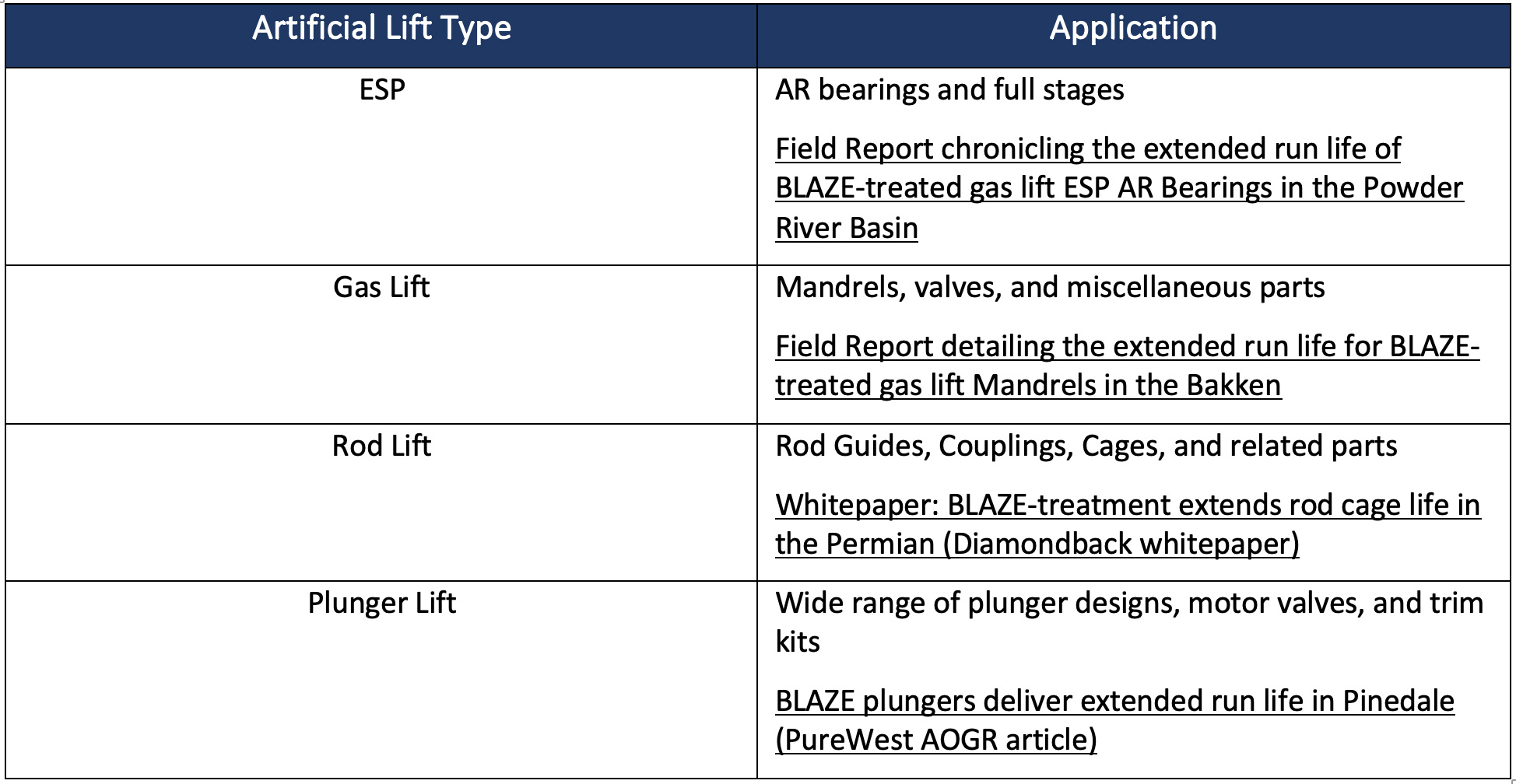

Since its introduction to the oil and gas industry in 2018, BLAZE®-treated parts have been used to extend the run life of a broad range of artificial lift systems—whether ESP, Gas Lift, Rod Lift, or Plunger Lift. Today, this proven metal surface treatment technology continues to prove itself in various oil and gas uses in all major domestic producing areas.

BLAZE-treated products have proven themselves in a wide range of applications, delivering up to 5X higher run life than conventional products.

BLAZE® Surface Treatment

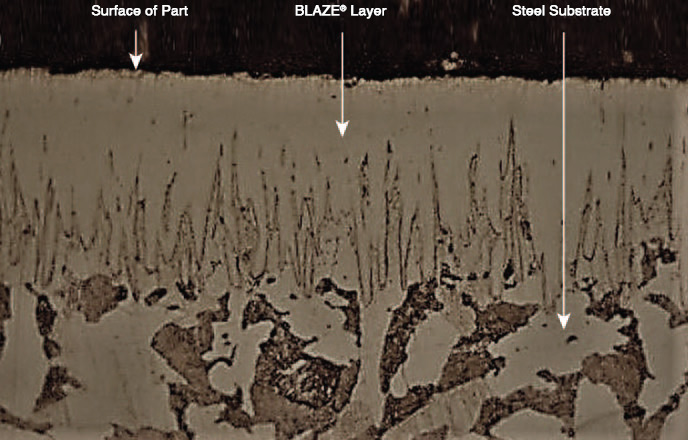

BLAZE surface treatment creates a slick, hard, intermetallic boride layer that (unlike coatings or plating) does not alter the dimensions of the part. This treatment’s slick, hard, and corrosion-resistant surface slows wear by protecting parts from the effects of abrasion, erosion, and corrosion.

In the BLAZE surface treatment process, boron is diffused into the steel substrate to produce a uniformly deposited boride layer at the substrate’s surface. Due to the combination of extreme hardness, abrasion resistance, and corrosion resistance, BLAZE-treated parts have consistently outlasted untreated parts in even the most challenging artificial lift applications.

BLAZE® Treatment as a Service

Proven in a wide range of oil and gas applications, BLAZE is also offered by Endurance Lift in the form of a Treatment as a Service (TaaS). We welcome the opportunity to work with you to determine if BLAZE surface treatment can benefit your application.

For more information on how Endurance Lift can bring the benefits of BLAZE to your application, please contact us at [email protected] or by phone at (713) 554-1399.