BLAZE® treated plungers and trim kits are getting dramatic results in key producing regions. BLAZE is allowing operators to extend the time between replacements using plunger lift, reduce production losses due to downtime, and lower equipment and repair costs.

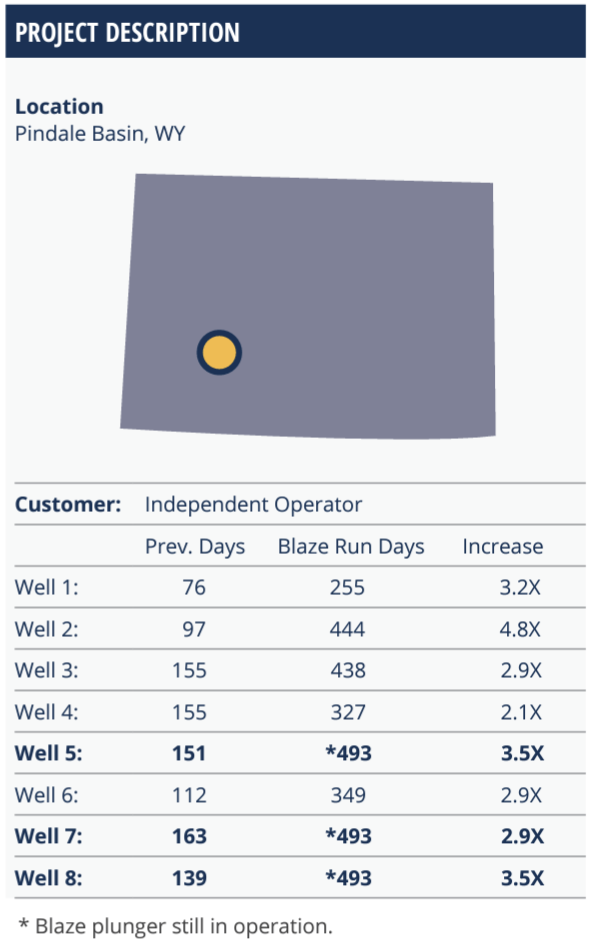

3.2x More Run Life than Bar Stock Plungers

In the Rockies, BLAZE treated plungers ran 3.2x longer than bar stock plungers on eight wells over an extended period, allowing the operator to cut replacement intervals, production losses and costs by 68.75%. Learn more in our field report.

5x More Run Life than Carbide Trim Kits

A Barnett Shale operator faced a challenging situation due to sand issues, replacing carbide trim kits approximately three times per month. With BLAZE treated trim kits, they were able to increase the run life of trim kits by more than 5x and counting. Learn more in our field report.

BLAZE® Explained…

BLAZE® is a Thermal Boron Diffusion Process that uses a proprietary chemical formula to produce a slick, hard, intermetallic Boride layer on metal surfaces. Unlike conventional treatments used on artificial lift components, BLAZE is not a coating or plating. BLAZE creates an intermetallic layer that cannot peel or crack and does not alter the dimensions of the part.

Not a Coating or Plating

BLAZE treated surfaces resist mechanical wear, corrosion, and abrasion – outperforming chrome, nickel carbides, and other alternatives. Because BLAZE outperforms everything, it is being used to treat a growing list of pumps, plungers, trim kits, valves, guides, couplings, and other components, helping operators set new artificial lift endurance benchmarks.

Learn More

Find out more about how BLAZE® surface technology is changing the game in artificial. Visit www.endurancelift.com/blaze.