Our Series 300 fiberglass sucker rods offer the industry’s highest load handling capacity, as well as superior performance in severe corrosion environments.

This solution enables our customer partners to increase production without up-sizing beam unit equipment, helping to reduce capital expenditures. Learn why more customers are turning to our Series 300 high-flow fiberglass sucker rods, featuring the world’s only “high-flow” fitting for high-production wells. Our proprietary predictive failure system for end fittings, found on every fiberglass rod we produce, virtually eliminates fiberglass rod body failures.

Series 300 Fiberglass Sucker Rod

Increased oil production through custom string design

Reduced electricity and capital costs due to decreased beam unit requirements

Extended run life in challenging deviated wells, reducing lease operating expenses

Broad range of sizes from pony rods to 37.5′ rod lengths and diameters of 1″ or 1-1/4″

Operating temperatures up to 185°F; alternatively, opt for our high-temperature rods for conditions up to 285°F

Reliability backed by our 24-month warranty

Pair this technology with our Blaze® rod couplings to dramatically reduce friction and compression in your rod string design, while enabling longer downhole stroke and reducing polished rod load

Series 300 HIFL Fiberglass Sucker Rod

Increased production with end fitting increasing flow area by over 40%

Over 60% reduced pressure drop across end fittings

Improve the effectiveness of your chemical program due to lower flow turbulence

Reduced stress loading on rod body

Hybrid 12-wedge design balances loading between wedges

50,000 psi working strength

1.8125” outer diameter

Standard 7/8” full size couplings; no diameter step between coupling and end fitting

Physical Specifications

Nominal Rod Diameter (in.)

1.00

1.25

1.25

End Fitting Type

API

API

HIFL

End Fitting Type Diameter (in.)

1.626

2.000

1.8125

Rod Weight @ 37.5' W/O Couplings

30.71

48.27

46.50

Rod Body Area (in2)

0.755

1.190

1.190

Weight per Foot @ 37.5' W/O Couplings (lb./ft)

0.82

1.29

1.24

Operating Properties

Standard Maximum Operating Temperature (deg. F)

185

185

185

High-Temperature Maximum Operating Temp. (deg. F)

285

285

285

Maximum Working Strength (psi)

50,000

50,000

50,000

Maximum One Time Pull Load (lbs force)

50,000

80,000

65,000

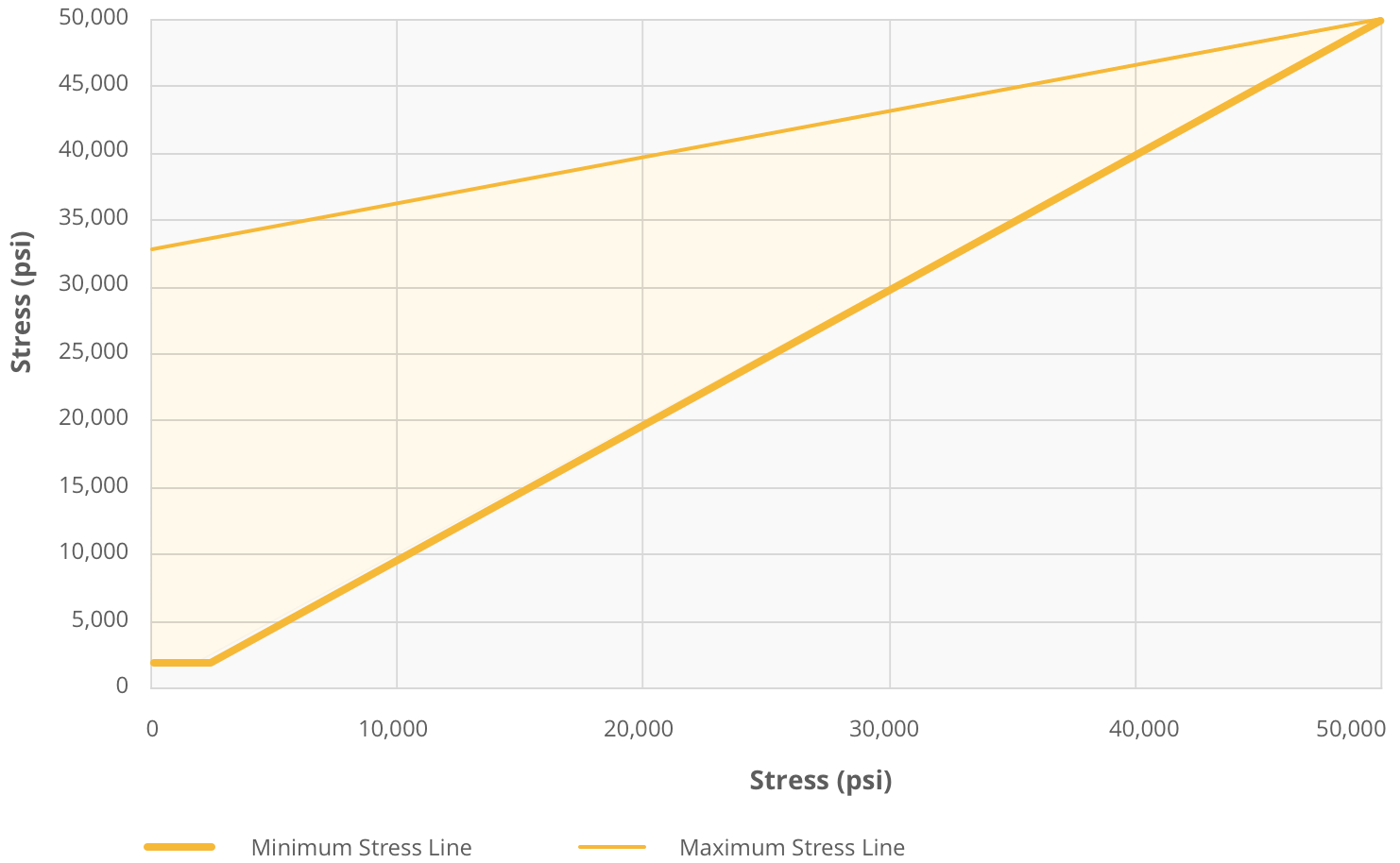

Allowable Stress Range Diagram