Many operators face a number of challenging well conditions in their artificial lift operations. Heavy concentrations of solids, high gas/liquid ratios, corrosive conditions, and more can lead to reduced production and equipment failure. These types of problems are commonly encountered across all forms of artificial lift, whether ESP, gas lift, rod lift, or plunger lift.

In response to these challenges, Endurance Lift has championed innovation to introduce significant new technology and products to enhance artificial lift recoveries and run life.

Endurance Lift’s Approach to Innovation

While our 15+ active or pending patents are evidence of our commitment to innovation, our focus has always been on applying technology that provides viable solutions to artificial lift problems. For instance:

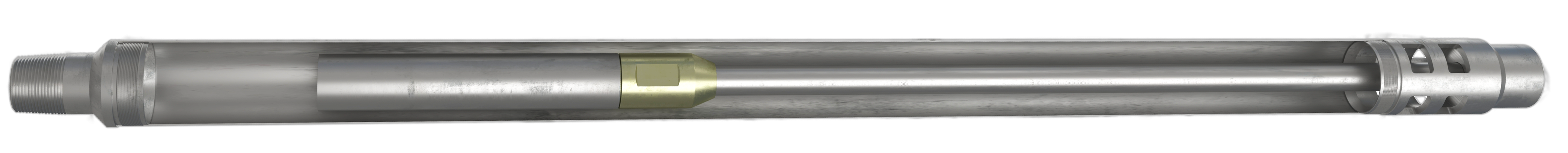

- Rod lift applications where the challenge posed by the presence of both solids and gas extends beyond the capabilities of standard BHAs – our new Guardian™ Sand and Gas Separator/Bypass TAC System is proven to deliver more gas-free, sand-free fluid into the pump, increasing overall system efficiency and extending run life.

Learn more here, or to contact one of our rod lift experts, email us at [email protected].  ESP applications where the challenge is declining wells with low intake pressures, decreasing fluid volumes, and increasing gas content – these issues can result in severe gas interference, shorter run times, production losses, and premature conversion to rod lift. Our Genesis Separation System is proven to handle up to 92% gas volume, a +20% improvement over conventional separator efficiency. This proprietary Endurance Lift system can boost production and also increase motor life. In addition, the Genesis system can extend the time an ESP can remain effective, postponing the production losses that will occur when a well must change to a different lift process.

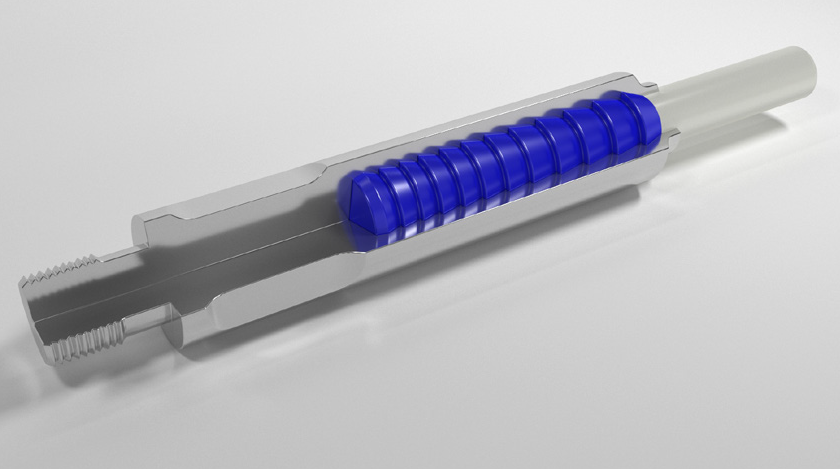

ESP applications where the challenge is declining wells with low intake pressures, decreasing fluid volumes, and increasing gas content – these issues can result in severe gas interference, shorter run times, production losses, and premature conversion to rod lift. Our Genesis Separation System is proven to handle up to 92% gas volume, a +20% improvement over conventional separator efficiency. This proprietary Endurance Lift system can boost production and also increase motor life. In addition, the Genesis system can extend the time an ESP can remain effective, postponing the production losses that will occur when a well must change to a different lift process.

Learn more here, or to contact one of our ESP experts, email us at [email protected].

Improving rod lift operations in demanding applications by substituting or combining conventional steel sucker rod with a proprietary fiberglass product – Endurance Lift’s FIBEROD® Fiberglass Sucker Rod (FSR) has been proven to increase oil production in a wide range of rod lift applications. Our patented Series 300 FSR offers the industry’s highest load handling capacity and superior performance in corrosive environments. Run earlier in the life cycle of a well to take the place of a second run ESP, FSRs routinely push boundaries of production past 400BBLS/day while providing extended run-times. Lighter in weight, as compared to conventional steel rod, the Series 300 FSR can reduce beam unit requirements and gear box loading, leading to lower energy usage and capex.

Improving rod lift operations in demanding applications by substituting or combining conventional steel sucker rod with a proprietary fiberglass product – Endurance Lift’s FIBEROD® Fiberglass Sucker Rod (FSR) has been proven to increase oil production in a wide range of rod lift applications. Our patented Series 300 FSR offers the industry’s highest load handling capacity and superior performance in corrosive environments. Run earlier in the life cycle of a well to take the place of a second run ESP, FSRs routinely push boundaries of production past 400BBLS/day while providing extended run-times. Lighter in weight, as compared to conventional steel rod, the Series 300 FSR can reduce beam unit requirements and gear box loading, leading to lower energy usage and capex.

Learn more here, or to contact one of our rod lift experts, email us at [email protected].

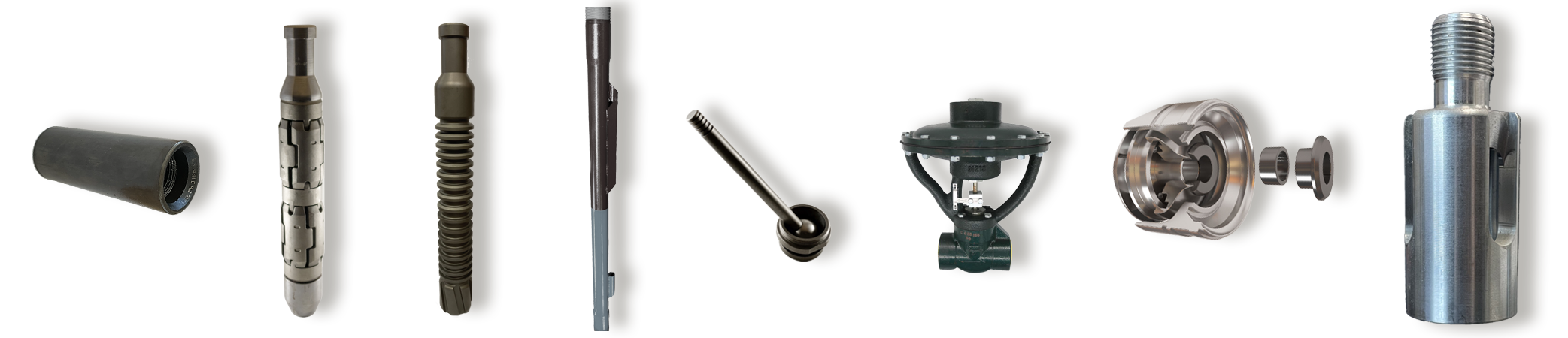

Building on a track record spanning more than four decades, Endurance offers a broad range of industry-leading plunger technology – whether your plunger lift application is best accommodated by a 2-piece, bypass or conventional plunger, we’re positioned to support the decline curve with innovative technology. Our new dart plunger is just one example – an industry first, short unibody dart with a center helix and bumper technology, which provides better fall speeds and greater flow area for highly deviated wells.

Building on a track record spanning more than four decades, Endurance offers a broad range of industry-leading plunger technology – whether your plunger lift application is best accommodated by a 2-piece, bypass or conventional plunger, we’re positioned to support the decline curve with innovative technology. Our new dart plunger is just one example – an industry first, short unibody dart with a center helix and bumper technology, which provides better fall speeds and greater flow area for highly deviated wells.

For more information, contact one of our plunger lift experts at [email protected].

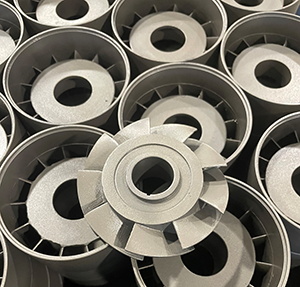

- Improving artificial lift performance and run life with BLAZE® technology – since 2018, we have been extending the run life of a wide range of artificial lift systems, some as much as 5X, by employing BLAZE® surface treatment to a wide range of parts and assemblies. BLAZE treatment has been used successfully across a wide array of artificial lift components, including couplings, plungers, trim kits, rod lift pump parts, gas lift mandrels, ESP stages, and motor valves, consistently improving part performance and run times.

Learn more here, or to contact one of our BLAZE experts, email us at [email protected].