Gas lift mandrels are under attack from the time they are run downhole, often being impacted by residual frac fluids and other elements found in the wellbore environment. In many applications, BLAZE®-treated gas lift mandrels are proving themselves better able to withstand a wide range of downhole conditions and provide significantly longer life than conventional mandrels.

BLAZE, a proprietary surface treatment, produces a slick, hard, intermetallic Boride layer within metal surfaces. This advanced treatment reduces friction and is highly corrosion- and abrasion- resistant, helping the mandrels withstand the effects of residual frac fluids and other elements that would damage conventional mandrels.

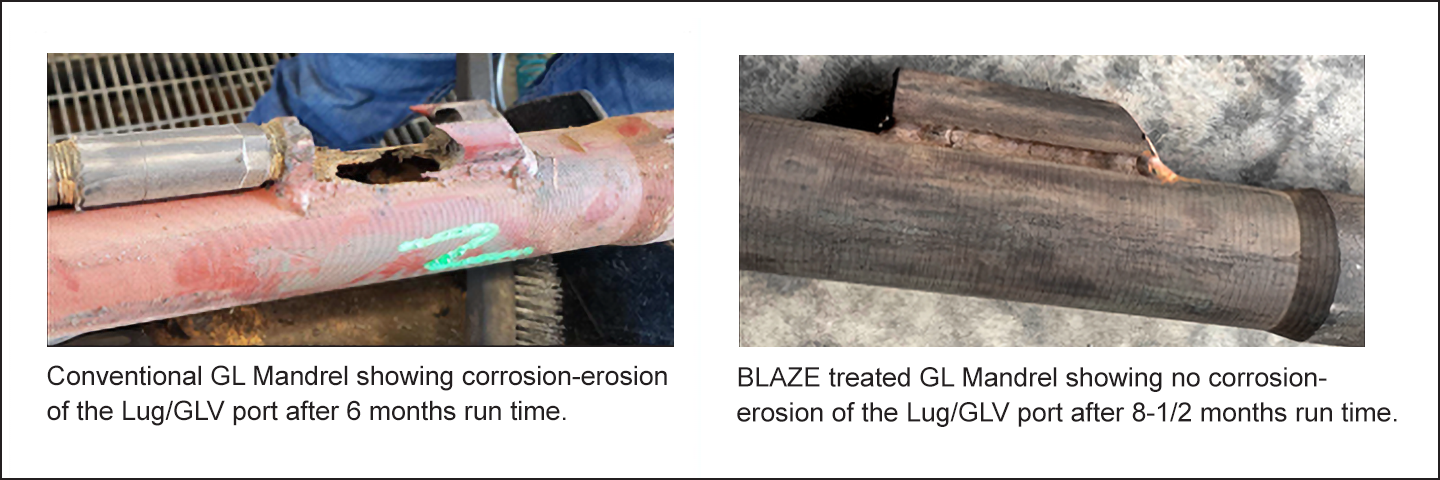

Recently, Endurance Lift teamed up with an operator in the Bakken whose wells had been washing out in as little as 6 months. These premature failures were caused by high velocity gas and sand, along with high levels of H2S corrosion. The result of these failures included almost a week in downtime and $500,000 in lost production revenue.

Endurance Lift addressed this issue by employing mandrels with BLAZE-treated bottom sections in lieu of traditional epoxy coating. After more than 8-1/2 months, the gas lift systems were pulled to protect against an offset frac. The BLAZE-treated mandrels showed ZERO corrosion/erosion wear. In fact, the mandrels were in such good shape, the operator is currently reusing them in other wells. This is the first time that this operator has ever been able to reuse gas lift mandrels.

For a Field Report detailing BLAZE-treated mandrels’ effectiveness in the Bakken, read more here.

Contact us at [email protected] to discuss how BLAZE technology can extend mandrel life.