The answer to mechanical wear, abrasion, and corrosion.

BLAZE® is a leading-edge Thermal Boron Diffusion technology that uses a proprietary chemical formula to produce a slick, abrasion-resistant, and corrosion-resistant surface.

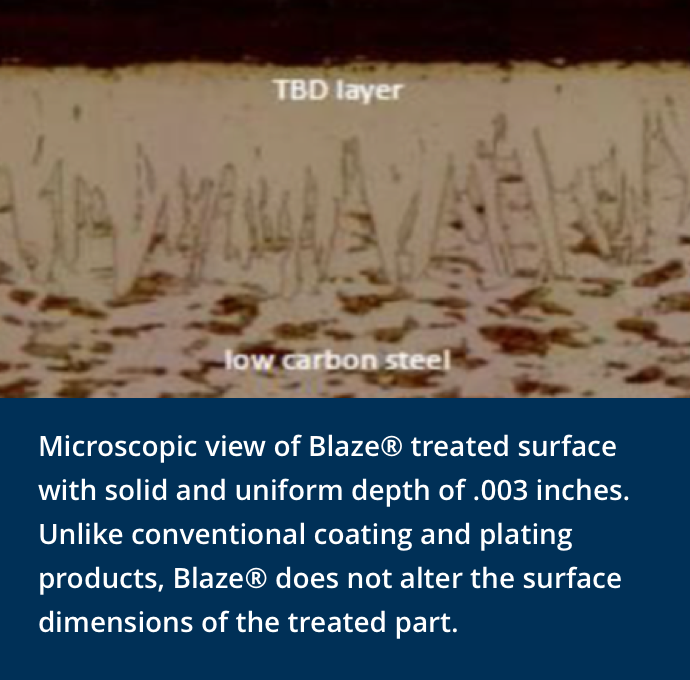

BLAZE creates a highly uniform surface with no change in original part dimensions. The BLAZE surface will not flake or chip under impact and poses no risk of delamination (“bonding breakdown”).

BLAZE® surface technology is not a coating or a plating. It is a revolutionary surface treatment that optimizes artificial lift performance and provides unmatched protection against friction, abrasion, and ESP corrosion. BLAZE makes artificial lift equipment wear better and last longer. In fact, BLAZE-treated surface reduces wear on artificial lift equipment and run times. (See lab tests and field reports for more information.)

Mechanical wear, abrasion, and corrosion are significant production challenges in any artificial lift environment. These challenges have a significant negative impact on the longevity of artificial lift equipment. BLAZE surface technology makes artificial lift equipment last longer, provide corrosion protection while dramatically increasing the efficiency of artificial lift operations.

BLAZE technology enhances the life span and optimizes performance of artificial lift equipment subjected to mechanical wear, corrosion and abrasion.

BLAZE® is compatible with a wide range of materials including cast iron, mild-carbon steel, chrome-moly steel, and stainless steel. BLAZE can be applied to a variety of Endurance Lift products to provide corrosion protection and prevention of abrasion, including plunger lifts, motor valves, downhole rod pumps, sucker rod couplings, ESPs, and more.

See BLAZE products for more information.